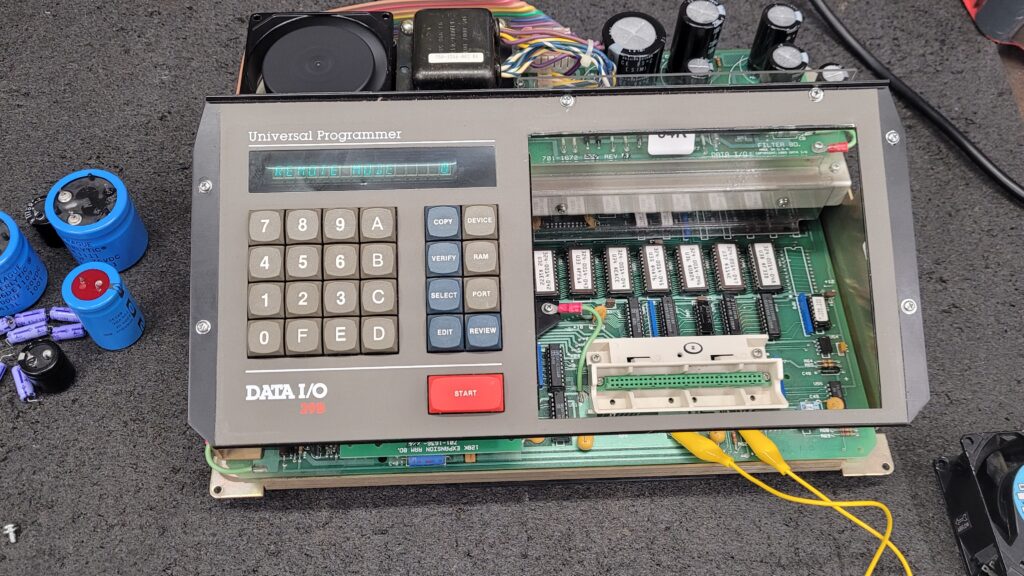

The Data I/O 29B programmers have been around for over 40 years, proving their durability and reliability. I’ve decided it’s time to give mine some well-deserved maintenance and Some community made upgrades, more ram, and USB for higher speed programming.. take it form 9600 to 19200! And Update Firmware to the last official update V6 will be programmed on New Old Stock 2732’s form ArcadeChips.com a reliable supplier of genuine older chips.

I currently own three 1980’s Data I/O 29B programmers two are fully functional, actively trying to earn their keep, while the third has a communication issue that I plan to resolve by the conclusion of this service. It’s remarkable how long these machines have lasted, a testament to the era in which they were built when manufacturers prioritized longevity and provided detailed repair documentation as standard business practice. Additionally I own a Data I/O 290o (Unifamily) and a Data I/O Chiplab.

Data I/O set the bar high by offering comprehensive manuals and schematics, to third party service centers ensuring the equipment they manufacture could be maintained and remain operational. The fact that these programmers are still widely in use today is a direct result of that philosophy. This is what Right to Repair is all about giving device owners the ability to service and maintain their equipment rather than being forced into unnecessary replacements.

From an economic standpoint, there is no modern equivalent that is both functional and affordable. Many of the devices these programmers support are still in use today, yet adding support for just one device on a new programmer can be prohibitively expensive. For example, I was quoted $2,000 just to add support for a single device on a BPM Microsystems FM1710 programmer an absurd cost for something that’s been around since the late 70’s and 80 and was once supported, and these low cost decades-old machines can handle effortlessly.

Without Right to Repair, industries reliant on some legacy hardware mostly manufactured after the mid 90’s would be forced into costly upgrades or even the discontinuation of vital production and repair services. The Data I/O 29B proves that well-built equipment, backed by proper repair and service documentation, can remain viable long past its expected lifespan—provided we have the ability to maintain and repair it.

I plan to get a modern Data I/O programmer but they are only economical on the second hard or as parts market. and recently i have had a couple people as if i can fix some they obtained as they are dead. I may be acquiring one of them dead Data I/O FlashPAK III

I reached out to Data I/O to determine whether they still support Right to Repair. Initially, getting a clear answer was challenging. A secretary or receptionist rudely dismissed my inquiry, saying, “We’re in Washington—those other state laws don’t apply, and we won’t comply unless the law requires it.” She refused to listen when I tried to explain how the laws might apply to Data I/O, but her stance hardly represented the company’s official position.

After a week of back-and-forth, their media relations team proved to be a dead end. So, I shifted my focus to tracking down the CEO. I believe I found his cell phone number—when I called, the voicemail simply identified him as “Bill.” I left a message and followed up with a text.

As I began working on the YouTube videos for this blog post, I received a call back from the Data I/O’s New CEO /President, William “Bill” Whentworth. We had a 30-minute conversation covering various topics, including Small Business and Right to Repair. Bill, who is new to his role at data i/o, seems to understand what we’re advocating for and what we’re seeking. He is currently handling several time-sensitive projects but asked me to send him an email to see what documentation he could provide. He also mentioned that he expects to have more time to focus on Right to Repair in May or June, once his current obligations are complete.

It remains unclear how far back Data I/O is willing to go in providing legacy documentation whether they will only comply with legal requirements or fully embrace the movement and go further, depending on document availability. Unfortunately, some records may have been lost to time it happens. I will provide an update on any progress in May or June. By then, Washington state may have passed its Right to Repair law, joining California, Oregon, Minnesota, Colorado, and New York, which have already enacted similar legislation. I may also have my Broken FlashPak III or Other Modern Data I/O programmer by then.

I will still be submitting my formal document and tool request, just in case things go south. I really hope for no AG Involvement.

There is a Really active Data I/O Community Supporting these Older Programmers Including an Unofficial Custom version of windows software that s evolving nicely.

Original Data I/O Groups (This is the best group)

Data I/O Facebook Group (New)

Windows Software PL2260+

The Service.

All Service Documents have been Obtained form the Data I/O User Group and Other Document Archive Resources.

All these units Will need the electrolytic caps replaced. I will prob service some of the tantalum at a later date they are a ticking time bomb especially the black bullets . I will Inspect the sockets, solder connections and refresh any cold or oxidized connection.

The Bare Minimum Necessary Capacitors!

List form Mouser as they had all capacitors in stock.

Display and Control Board Capacitors.

Capacitor Axial 47uf 100V X 3

https://www.mouser.com/ProductDetail/594-2222-021-39479 (These are Vishay Brand, I would like to find some 105C Rated Axial Nichicon/Panasonic or other Name Brand Caps)”

Capacitor Axial 47 63v X 4

https://www.mouser.com/ProductDetail/594-2222-021-90542 (These are Vishay Brand, I would like to find some 105C Rated Axial Nichicon/Panasonic or other Name Brand Caps)

Filter Board Capacitors,

Capacitor C1 | 5600 100V X 1

https://www.mouser.com/ProductDetail/647-LLS2A562MELC

Capacitor C3 | 2200uf 100V X 1

https://www.mouser.com/ProductDetail/647-LGY2A222MELA50

Capacitor C10, C6 | 1500uf 50V X 2

https://www.mouser.com/ProductDetail/647-UHE1H152MHD

Capacitor C9 10000uf 25V X 2

https://www.mouser.com/ProductDetail/647-LGY1E103MELZ40

Capacitor C9 Notes.

You Can Use Any 2 Capacitors 8600uf to 10000 25V I went with two 10000uf due to Costs it was few bucks cheaper and Available in 105C Rating. I could have went with a single 20000uf but that was not optimal and had high esr putting more demand on the MDA970A1 Rectifier that I did not want according to the limited info the data sheet a charge time of 15 to 22ms is ok I think the transformer can handle the increased inrush current time will tell..

The Good, Better ripple filtering (lower ripple voltage)., More stable output under load., Lower ESR (better transient response)

The Bad, Increased Inrush Current, When the power supply first turns on, the capacitors charge up quickly causing a surge in current., Costs about 1.5X more then a single capacitor.

I would provide a mouser project list but stock is always changing

Repairing vintage stuff for almost 30 years I see common parts that fail. I think I will be electing to replace a few more parts I will post the mouser / digikey or other vendor part #’s

Fan, I went with the AC Infinity on a recommendation. It’s acceptable but i think i can find a better solution. “No Not RGB”

I am go going to get in to how to open the unit up it is self explanatory, If you are unable to figure it out you should not be attempting this referd to a qualified professional. Photos below were taken over the service of my 3 units so PCB showing Revision’s may be different but the repairs are the same.

First Target is the Power Supply Filter Board.. This is the later Revision.

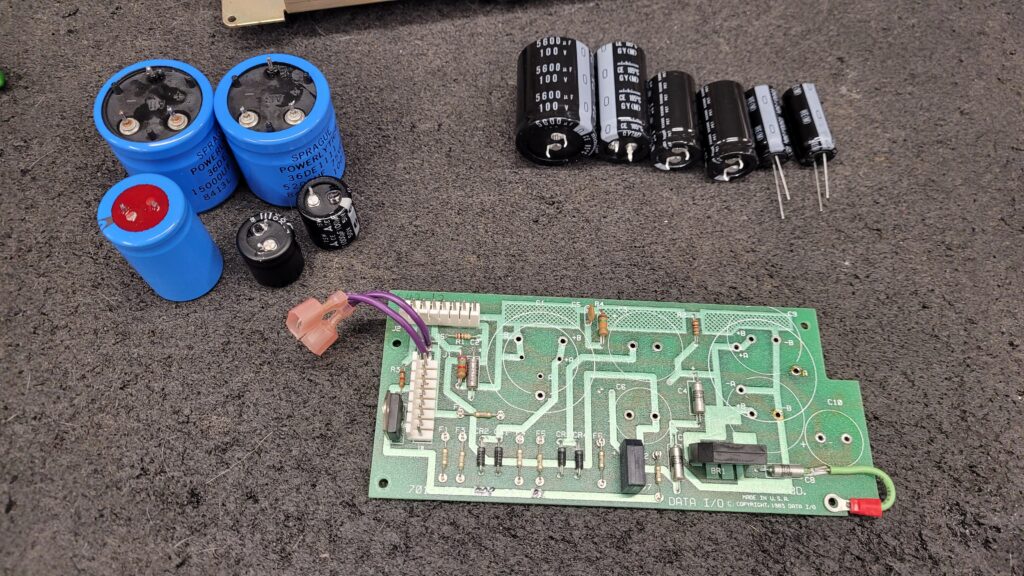

Capacitors Removed.. New ones Ready to Install. Older PCB Revision.

Take note that C1 5600Uf 100V Cap has 10MM Lead Spacing and the Pads on the boards have 15mm and 18mm so you will need to use pads A+ an A these are 10mm spacing you will then need to run a bodge wire on the bottom From Pad A to Pad A- See Video. I think there are open source 3 pin adapter boards for accomplishing this task but this works as well.

Bottom Photo Bodge.

New Capacitors Installed in the Data I/O 29B Filter Board (Later Revision) Modern Caps are a bit skinnier and this should help with airflow reducing heat.

There is a Data I/O 29B filter service update Here (Archive) on the filter board removing fuses and replacing them with jumpers, adding a ground wire that is the “green wire with ringred terminal in photo above.

Thoughts, This is a simple power supply filter board, There could be some improvements #1 if with parts availability and fuses in sockets. #2 Rectifier Cooling, #3 Response Time, So I am officially starting a project to make a modern filter board using parts that are readily available. I Have only done the board measurements in easyeda pro and studding up more on power filtering theory it will take some time. I am not a engineer but a decent reverse engineer and like to learn lol.

Additionally, I have been given the opportunity to Learn DipTrace PCB EDA so I think this project will be a good one to learn the software on I will, most likely be live streaming my experience learning Dip Trace as i have the time to do so.

(Photo)

Data I/O 29B Display Board,

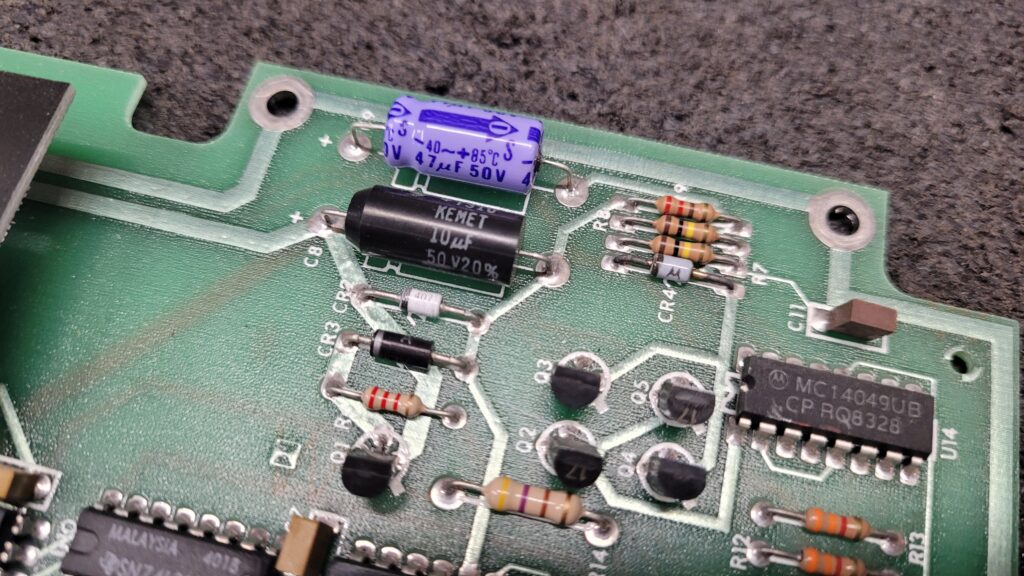

The Display Board Has 2 Electrolytic Capacitors.

At Location C8, I was Unaware of the Black Bullet Capacitor that is a 10uf 50V it should be replaced these type of caps have a exceptionally high failure rate in other devices I don’t trust them.

Capacitors Removed

New Capacitors Installed On the VFD baord, As soon as the Replacement for C 8 Arrives I will update the List and Part Number. I would have thought someone would have made a a OLED replacement for this by now. I have not seen if that VFD is common or even if a replacement is Available.

As said there is thriving community on these data I/O 29B Programmers. A Great example is a A Data I/O group member made a replacement key board that takes modern cherry mechanical switches and caps. Download the PCB Gerber Files Here (Archive) EasyEda PCB File generated from gerber files. I Plan to Build a couple up for a Just in-case i need one cinaro, as we all know these are obsolete. I need to order 5 PCB’s so i’ll build 2 or 3 and will “give-away” the extra 2 or 3 blank pcbs for others to build. Keybaord PCB Rendering From EasyEDA Ocne I build one I will update photos.

Data I/O 29B Main Board Capacitors there are 5 of them.

Data I/O 29B Main Control Board Capacitors Removed. I do have 1 missing and one broken stand off the height is about 20mm I was thinking of using modern screw type stand offs and replace all 4 of them.

New Capacitors Installed in the Data I/O 29B Main Control Board

All 3 Boards Ready to Re Assemble and Test the Baord on the Left is the 64k Memory Board will discuss the upgrade options later.

ReAssembly Reverse Order 29B Control Baord Memory Board Installed Cable Connected)

Keyboard and Power Supply Filter Board Connected

Power Up.. See Video! No Magic Smoke Escaped

{Video}

I Installed a Unipack2B and launched PL2260+ and it connected I tried a couple devices 1 high voltage device and a few others and things seem to be filly operational. I am sure the main board and other items are happy with clean power. I will put it on the bench and preform the 29B Acceptance Test procedures form the Data I/O publication Here (Archive). I will also put it on the bench and check voltage and ripple current with the scope etc. But I am confident that this service will make the unit happy.

Since I was doing all 3 of these Data I/O 29B’s and had the boards out.. The one that will not communicate has faulty MC1488 Mc1489 chips.. I have them in my card just have not ordered them Yet as i think i am going to convert this unit to USB. Another Data I/O Group user made a simple add-on board to accomplish this task Here. (Archive) Another member also made a 512-1meg expansion board. Here (Archive)

There are many user created upgrades and accessories and the older these get it seems

I Have Both Boards ready to assemble. I will Update when I get the time to do it.

But Since i had the board out I would remove the bad chips until i decide what i am going to do.